- Oct 25, 2007

- 115

- 26

By request here's a tutorial on how to make Displacements Pipes and Sewers. I believe this is how it was done for 2Fort Sewers and it's how I did it in my map Jinxed.

I'm going to show you how to do the most complex type (sewers you can go inside of and see from the outside) but you can adapt to your taste.

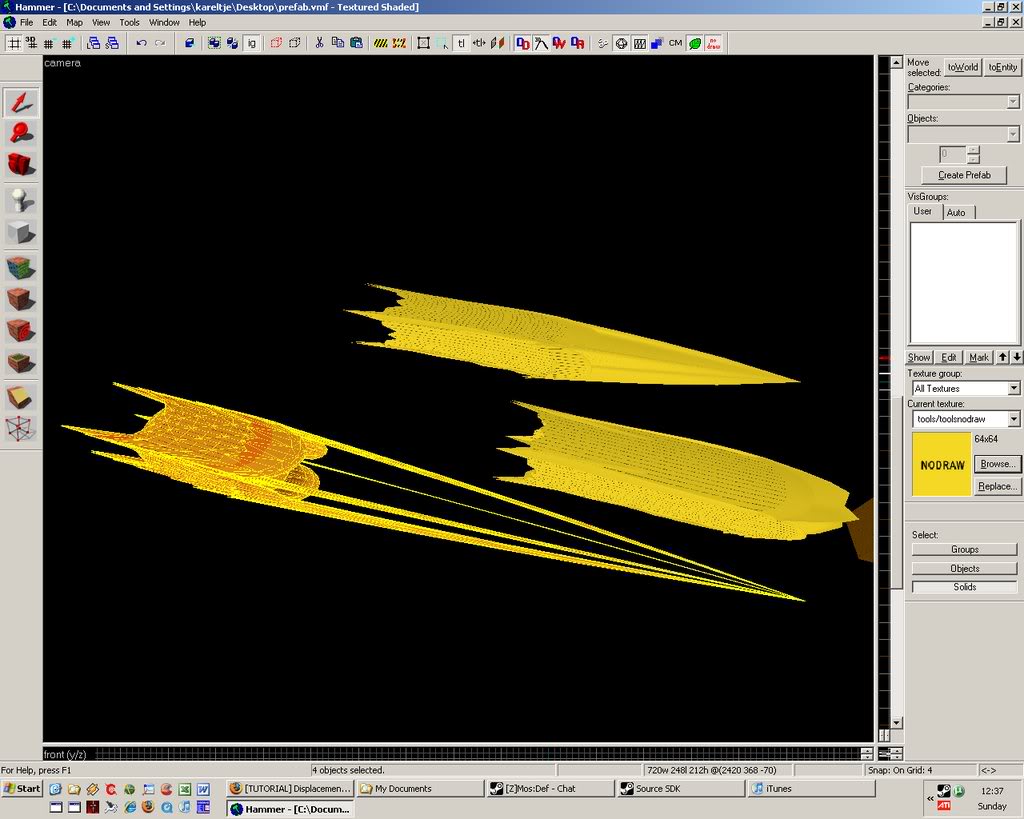

Each number has a corresponding image attached.

(1) Create your Starting Block. If you want to use the sewer cap model I recommend 240x240 (Length is up to you. Seen in the screen shot is 256x256 which is perfect for sewers that you will run through but can't see from the outside (like 2Fort) but a little large on the outside of the sewer cap model. The length of the block doesn't matter and you can change it later if it's too short or too long.

(2) Hollow out the block you made. Again my recommended is 8 but you can play around with it to your liking.

(3) Delete the two square sides of the block as show.

(4) Using the vertex manipulation Tool Bevel your edges like so. This is important to do for later on

(5) Create your displacement by selecting all of your brushes and going into the face edit/texture tool (can't look at exact name right now) and clicking "Create" under the displacement tab.

On to Part II....

I'm going to show you how to do the most complex type (sewers you can go inside of and see from the outside) but you can adapt to your taste.

Each number has a corresponding image attached.

(1) Create your Starting Block. If you want to use the sewer cap model I recommend 240x240 (Length is up to you. Seen in the screen shot is 256x256 which is perfect for sewers that you will run through but can't see from the outside (like 2Fort) but a little large on the outside of the sewer cap model. The length of the block doesn't matter and you can change it later if it's too short or too long.

(2) Hollow out the block you made. Again my recommended is 8 but you can play around with it to your liking.

(3) Delete the two square sides of the block as show.

(4) Using the vertex manipulation Tool Bevel your edges like so. This is important to do for later on

(5) Create your displacement by selecting all of your brushes and going into the face edit/texture tool (can't look at exact name right now) and clicking "Create" under the displacement tab.

On to Part II....